SAP Routing Tables hold the information in an order about the activities performed at the work center. The data about routing have a crucial role in estimation and calculation of production cost, machine and labor time.

Whenever, you intend to develop a routing, never forget to create work center at first step. Create routing groups and multiple and diverse materials can follow via sole routing group. SAP Routing Tables also assist in scheduling and costing of operation for raw and finished products.

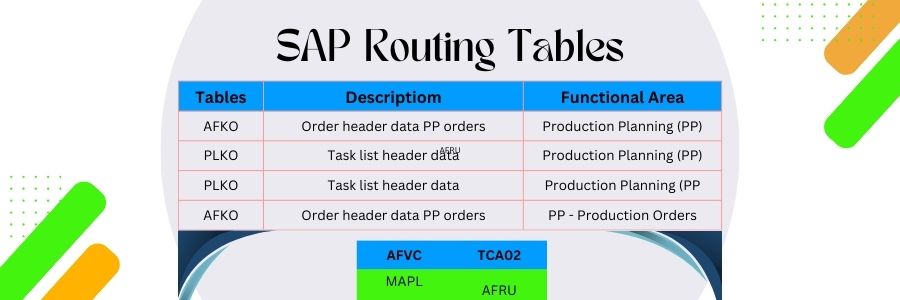

| Tables | Description | Functional Area |

| AFRU | Allocation of capacities and routing in production orders | Production Planning (PP) |

| CRHH | Work center hierarchy | Production Planning (PP) |

| CRHD | Work center header data | Production Planning (PP) |

| CRCA | Work center capacity allocation | Production Planning (PP) |

| TC02 | Control parameters for scheduling | Production Planning (PP) |

| PLKO | Task list header data | Production Planning (PP) |

| PLAS | Task list – selection of operations/activities | Production Planning (PP) |

| MAPL | Assignment of task lists to materials | Production Planning (PP) |

| AFVV | Order operations | Production Planning (PP) |

| AFVC | Operation within an order | Production Planning (PP) |

| AFVG | Collective confirmation for order | Production Planning (PP) |

| AFVV | Order operations | Production Planning (PP) |

| CRCA | Work center capacity allocation | Production Planning (PP) |

| AFRC | Confirmations information | Production Planning (PP) |

| TCA01 | Language-dependent texts for TCA01 | Logistics – General |

| TCA02 | Language-dependent texts for TCA02 | Logistics – General |

| TCA03 | Language-dependent texts for TCA03 | Logistics – General |

| TCA04 | Language-dependent texts for TCA04 | Logistics – General |

| TCA05 | Language-dependent texts for TCA05 | Logistics – General |

| TCA06 | Language-dependent texts for TCA06 | Logistics – General |

| TCA07 | Language-dependent texts for TCA07 | Logistics – General |

| TCA08 | Language-dependent texts for TCA08 | Logistics – General |

| TCA09 | Language-dependent texts for TCA09 | Logistics – General |

| TCA10 | Language-dependent texts for TCA10 | Logistics – General |

| PLPO | Task list – operation/activity | PP – Routing |

| MAPL | Assignment of Task Lists to Materials | PP – Routing |

| COPLPO | Transfer Structure of routing operations to Order | PP – Production Orders Structure |

| PLMZ | Allocation of bill of material items to operations | PP – Routing |

| AFKO | Order header data PP orders | PP – Production Orders |

| MARC | Plant Data for Material | Logistics – Material Master |

| RESB | Reservation/dependent requirements | MM – Inventory Management |

| STOP | BOM item | Logistics – Bills of Material |

| PASST | Strategies for Partner Search | MM – Purchasing |

| MAST | Material to BOM Link | Logistics – Bills of Material |

| PLPOD | I/O table for task list operations and network activities | PP – Routing |

| MARA | General Material Data | Logistics – Material Master |

| MONI | Monitor table MONI | Basis – Performance Monitors (TCC) |

| AUFK | Order master data | CO – Overhead Cost Orders |

| JEST | Individual Object Status | Cross Application – General status management |

| RESP | Project Number for SAP Partner | Basis – Transport Organizer |

| STXH | STXD SAP script text file header | Basis – SAP script |

| MPOS | Maintenance item | PM – Maintenance Task Lists |

| STKO | BOM Header | Logistics – Bills of Material |

| AFVGD | Order: Dialog table for Table AFVG (order operation) | PP – Production Orders |

| CRCO | Assignment of Work Center to Cost Center | PP – Work Center |

| PLMK | Inspection plan characteristics | QM – Inspection Planning |

| PLFH | Task list – production resources/tools | PP – Routing |

| PLFL | Task list – sequences | PP – Routing |

| PLKZ | Task list: main header | PP – Routing |

| PLPH | CAPP: Sub-operations | PP – Computer Aided Process Planning |

| PLWP | Allocation of maintenance packages to task list operations | PM – Maintenance Task Lists |

| PLAB | Relationships | Project Systems – Network and Activity |